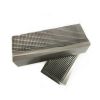

Screw Thread Rolling Die

Screw standard: JIS, DIN, ANSI, BS and etc.

Material: DC53 and M2.

Point type: Type A, type AB, without a point, and so on.

Pattern Dimensions: Length up to 510mm and Width 155mm with any thickness.

Pattern Type: Flat

Hardness:DC53: 63 degree ; M2: 63-64.5 degree

Price: 0 ₫

Advanced screw thread rolling machines and technology talented persons guarantee the high output, high quality, and high-speed production of our company.

1.Please indicate the following details when to inquiry or order:

1. Major Diameter

2. Machine Model, Machine Maker, or Dieplates Size

3. Screw head style, size, and length.

The special specification of customized design is available, please send the drawing with details for reference when inquire or order.

2.SHOME dies are developed to help roll the best quality fasteners without modifying any of the processes (e.g. blank preparation and machine operation). In controlling manufacturing variables to yield Lap free thread fasteners;

- Helps maintain normal production rates and machine speeds – even when rolling critical fasteners with after heat treatment(AHT) blanks.

- Enhances control of grain flow, whereby LT dies to begin forming the thread crest almost immediately; no other thread rolling dies in the world has this capability.

- Improves Physical characteristics of the fastener due to the controlled nature of material displacement. Specifically, the smooth surface finish and compressive residual stresses introduced by rolling make rolled fasteners Stronger in fatigue, shear, and tensile strength.

Photomicrographs of high-quality conventional thread showing crest seam:

Smooth, Even Finish – No Die Serration Marks because of their improved thread forming an action, LT dies do not use cross-nicking to prevent skidding or slippage. As a result, root defects caused by the rolling process such as laps and scalloping are eliminated.

3.Special Coating:

Special surface treatment XDL suitable for High-speed steel and premium tool steel dies that increase the performance of our Thread Rolling dies and longer tool life, increased wear resistance, reducing machine preps and changes and minimizing the machine downtime, and making our dies commercially viable by reducing cost per pc.

Further, the good lubricating properties of the coatings minimize friction at the tool–chip and tool-workpiece interfaces, thereby lowering the cutting temperature. All these translate into lower forces generated during machining compared to uncoated tools.” This will help in increasing the tool life.

4.After Heat Treatment:

Special Thread Rolling Dies are manufactured to roll hard to roll the after heat treatment ( AHT )parts in 8.8, 10.9,12.9 classes or hard to roll materials such as stainless steel and high tensile steels.

The advantage of doing thread rolling after heat treatment is that it improves the strength of the bolt and gives a longer service life and performance of the bolt.

Also, rolling off the hardened fastener materials results in more frequent die replacements on rolling machines, reducing production rates and increasing costs.

Đánh giá 0 lượt đánh giá

We always believe that people are the most importar it factor and the key to all success. Therefore, the team of leaders and employees at Shome Vietnam are all virtuous and talented, with high qualifications, professional working style, constantly striving to improve themselves and develop the company.