Chipboard Screw

- Product name: Chipboard Screw/chipboard screws with saw/spax screw/sawed chipboard screw

- Material: Carbon steel, stainless steel, brass.

- Head type: flat/countersunk, pan, Double Flat, wafer head, CSK with 4(6) ribs

- Finish: zinc plated, Black Oxide, Nickel, Rupert, Dacromet, and so on

- Drive Type: Phillips, Pozi, square, Torx

- Standard: DIN7505

- Packing: bulk, plain box, color box, polybag, PP box + wood Pallet

The Feature of Chipboard:

- Easy to screw in

- High tensile strength

- Avoid cracking and splitting

- Deep and sharp thread for cutting through wood cleanly

- Excellent quality and high-temperature treatment for resistance to snapping

- Different choices of dimensions and surfaces

- Construction authorities approved

- Long service life

Chipboard screws, also named particleboard screws, are self-tapping screws with thin shafts and coarse threads. They are made of carbon steel or stainless steel and then galvanized. Chipboard screws of different lengths can be used in a variety of applications. They are created to fasten low, medium, and high-density chipboard. Many chipboard screws are self-tapping, so there is no need to drill holes in advance.

SHOME is a professional chipboard screw manufacturer and we offer a great variety of chipboard screws: in terms of the head type, we offer double countersunk head type and flat head type; besides, we also provide chipboard screws with nibs under the head.

2.Specification of Chipboard Screw:

As a professional chipboard screw manufacturer, we provide a wide range of chipboard screws. The main sizes are the following.

3.Application of Chipboard Screws

- Be widely used in the structural steel industry, metal building industry, mechanical equipment industry, automobile industry, etc. Ideal for chipboards and wood, they are often used for cabinetry and for flooring.

- Common length (around 4cm) chipboard screws are often used to join chipboard flooring to regular wood joists.

- Small chipboard screws (around 1.5cm) can be used to fasten hinges to chipboard cabinetry.

- Long (around 13cm) chipboard screws can be used to fasten chipboard to chipboard when making cabinets.

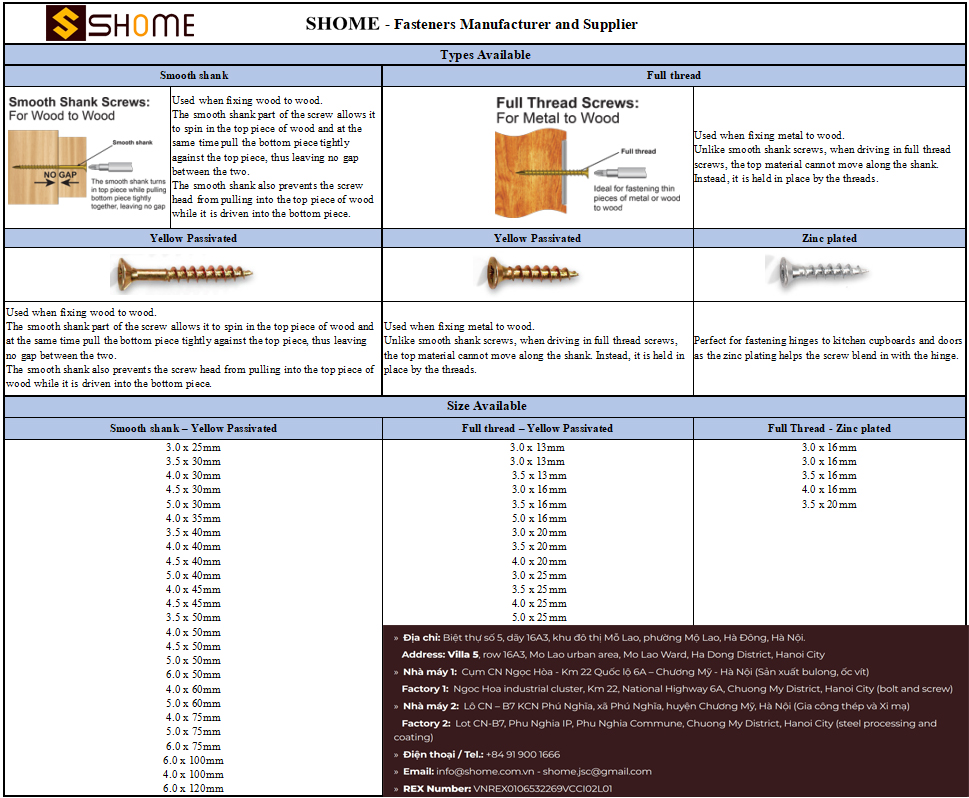

4.SPAX Wood Screws (Chipboard Screws Countersunk Head, Saw Tri-Claw Thread Galvanised Yellow Chromated)

(1). Descriptions:

The Galvanised Chipboard Screw has a coarse thread and a fine shank to maximize grip into chipboard, MDF, and other soft timbers. The head has nibs which help to remove the chipboard particles when countersinking. The galvanized coating is suitable for most outdoor applications.chipboard screw or particleboard screw is a self-tapping screw with a thin shaft and coarse threads. Chipboard is made up of resin and wood dust or wood chips, so chipboard screws are made to grip this composite material and to resist withdrawing. The screws solidly fasten chipboard to chipboard or chipboard to other materials such as natural wood.

Chipboard screws come in a variety of lengths and can be used to fasten chipboard in a variety of applications. Average length chipboard screws are often used to join chipboard flooring to regular wood joists. Smaller screws may be used to fasten hinges to chipboard cabinetry. Very long screws may be used to butt chipboard to chipboard when making cabinets. Average screws are 1.5 inches (around 4 cm), small screws are usually ½ inches (around 1.5 cm), longer screws are 5 inches (around 13 cm).

Different shapes and materials of chipboard screws are common as well. The most common screws are made out of zinc, yellow zinc, brass, or black oxide. Popular heads are either pan, flat, or bugle, and popular gauges are 8 and 10. Screws may have Phillips or square (Robertson) screw drives.

(2).MULTI HEAD:

Cutting ribs help the head countersink.

Screw head ribs help reduce the thread being stripped when fixings hinges etc.

Deeper recess for stronger bit hold.(3).CUT POINT:

No Splitting even when working close to the edge.

No pre-drilling required even in hardwoods.

Screw point takes immediate hold.(4).GROUND SERRATIONS:

Reduces driving in torque.

Hard Synthetic coating for easy driving.

Ultimate holding power.Welcome to contact our chipboard screw factory for the order. May SHoME be your reliable chipboard screw manufacturer for long-term cooperation.

We always believe that people are the most importar it factor and the key to all success. Therefore, the team of leaders and employees at Shome Vietnam are all virtuous and talented, with high qualifications, professional working style, constantly striving to improve themselves and develop the company.